April

2023

Safety first with the right ELECTRICAL INSULATING MATTING

Electrical insulating matting is the right choice for high-voltage workspaces. It comes in various colors, classes and surface profiles. Learn everything you need to know before and after investing in a life-changing safety measure.

An example of an electric insulating matting class 3

In this article, we will explain what Electrical insulating matting is, what is the difference between the 5 recognised classes, what is a marking tape and why it is a crucial part of every mat. We will later discuss the need of procurement and inspection of insulating products and how to properly take care of them. The article will then move on to talk about the importance of colours of EIM and how we at BOGUMA ensure the quality of our electrical mats.

Every job entails some risks, and this is especially true for workplaces where you are in regular contact with high voltage. Whatever the field of work, it is important to use insulating materials that help minimize the risk of electric shock and ensure the safety of your employees. You will come across different types of protection, but choosing the right one can seem challenging. Since you are deciding on the quality of life protection for your employees and colleagues, the choice should not be taken lightly. However, your decision does not have to be a lengthy stressful process, you just need to know what to watch out for.

Electrical insulating matting (EIM) is a rubber insulation layer used for additional protection in transformer and power distribution stations in high-voltage workplaces, or in front of electric switchgear in buildings. EIMs are an integral part of these workstations, but not their primary protection, so other protective equipment such as suitable non-conductive work boots and protective gloves must also be worn when performing tasks in high-voltage workplaces.

EIM is mainly used by professionals and is not suitable for ordinary tasks. The mats decrease the hazard of working with live electrical parts and increase the safety of employees, therefore it is the best product on the market for preventing injuries in high-voltage spaces. Professionals should choose Electrical insulating matting based on the station or electric switchgear they operate in, that is why we offer various types of EIMs in classes 0 to 4.

The 3 most commonly used types of mats among our 227 clients in more than 30 countries around the world are DEK3S1-2, DEK2-S7-1 and DEK4-S7-1. As you can see, the choice of matting is not uniform due to the different criteria of each client that suit their specific environment. What is then the main difference between these examples?

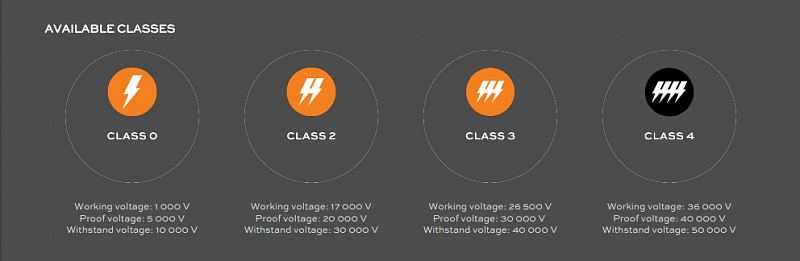

Classes of EIM

Electrical insulating mats are divided into classes that help our clients differentiate between our products based on the needs of their projects. Mats start with a working voltage resistance of up to 1,000 volts, but we also have those that are resistant to a working voltage of up to 36,000 volts. They have a similar surface appearance but differ in thickness.

We recognise 5 classes of Electrical insulating matting from 0 to 4 according to the IEC 61111:2009 standard. IEC 61111:2009 is applicable to Electrical insulating matting made of elastomer for use as a floor covering for the electrical protection of workers on electrical installations.

| CLASS | CLASS COLOR | WORKING VOLTAGE | AVAILABLE PRODUCTS |

| Class 0 | red | up to 1,000 V | DEK0-S7-1 & DEK0-S7-26 |

| Class 1 | up to 10,000 V | ||

| Class 2 | yellow | up to 17,000 V | DEK2-S7-1 |

| Class 3 | green | up to 26,500 V | DEK3-H0-1, DEK3-H1-1, DEK3-S1-2 |

| Class 4 | orange | up to 36,000 V | DEK4-H0-1, DEK4-H-1-1, DEK4-S7-1 |

A product that is not certified according to the IEC 61111:2009 standard is not suitable for high-voltage workplaces. Such product is dangerous to employees and inspectors because it does not meet the conditions for use in high-voltage places. There are some more details you should look for when choosing the right matting.

Types of available classes with their Working, Proof and Withstand voltages

Marking tape

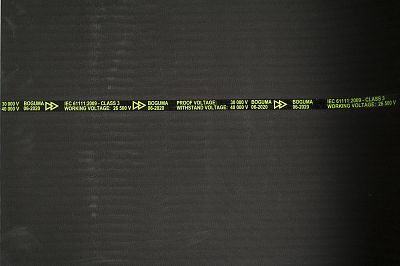

The insulating matting is (ideally) marked with a vulcanized marking tape along the entire length of the mat from the underside. This method of marking is permanent and cannot be erased.

The marking tape must contain:

- Class name

- Manufacturer name

- Double triangle in the colour of the given class

- IEC Certification

- Manufacturing date

- Working voltage

- Proof voltage

- Withstand voltage

EIM must always be accessible for inspection to determine whether it meets the conditions of the relevant workstation. Therefore, we do not recommend glueing Electrical insulating matting to the floor, as it becomes more difficult to determine whether the matting used is appropriate for a particular workplace.

An example of a marking tape on an electrical insulating mat

Procurement and inspection

Insulation mats, unfortunately, do not last forever and according to IEC 61111:2009, they need to be inspected by a qualified technician once every 12 months. We guarantee that our products have been properly tested, therefore, the first inspection can be carried out 12 months from the date of release from the factory.

Generally, rubber products have a lifespan of 5 years according to European standards and conventions. Even in case of a problem-free inspection, we recommend replacing your mats every 5 years. After this time, the material may have changed properties, such as a hardened surface, which does not meet the quality requirements. It must not have any surface damage, as this causes weakened protection, making the mat unusable. When any surface defect is found, the matting must be replaced immediately in the interest of the employee and inspector's safety. If you want to make sure your mats last the recommended 5 years without any damage, it is important to take care of your products properly.

Product care

To secure a long-lasting quality of your mats, they must be preserved correctly. Each product or a series of products of a similar type is maintained differently. Some products can be even washed with liquids, however, for electrical insulating products, such as Electrical insulating matting, we advise you to not wash it with water as it is not a floor covering for exterior surfaces. We recommend sweeping the mats dry with a standard broom, whisk broom, or wide broom to prevent losing their desirable insulating properties and to protect the workers properly.

When cleaning, if you notice any damage, replace the mat immediately. It is possible that dirt and debris can get on the mat, but since switchboards are under electrical voltage, people should not step on them with muddy shoes because the mentioned contaminants are wet and, therefore, conductive. Typical dirt, however, usually comes in the form of dust, which can be easily removed.

Colours of EIM

What might be surprising is that even the colour of EIM plays an important role in your decision process. We focus on manufacturing Electrical insulating matting in shades of black and grey. The difference between them is primarily their working voltage resistance.

The grey EIM has higher strength parameters, higher resistance, and can be used for higher voltage under certain conditions and thicknesses than black. We can produce grey matting with working voltages of 36,000 volts and withstand tests up to 50,000 volts that meet Class 4 parameters.

Nevertheless, if the environment you wish to insulate does not require such strong resistance, we recommend you choose the black option. Black is used for Class 3 voltage, up to a maximum of 26,500 volts of working voltage, and thus can still be used for a variety of high-voltage places.

Our EIMs rightfully possess the mentioned IEC certificate. Since 2007, we have owned certificates, and we are gradually renewing them, which is one of the indicators of the quality of our products. We exclusively produce insulation matting from various verified suppliers from the Czech Republic with whom we have been collaborating for more than 10 years. These companies manufacture quality rubber mixes for our insulation matting production.

We test products before releasing them from production, and we can also show interested parties and customers our production, which we have already done in the past. During this tour, you can see the material we use, and how we process, manufacture and test the Electrical insulating matting.

Another quality aspect we are proud of is our employees. A third of them have been with us for more than 10 years and have the necessary know-how and experience. You can count on our team of rubber specialists to help create quality products that will not disappoint your expectations.

We hope that this informative summary helps you with making the right choice when looking for the ideal matting for your workspace. If you have any more queries, we will happily get in contact with you through our email: info@boguma.sk

And for more detailed parameters of the Electrical insulating matting we manufacture, click here.

IEC 61111:2009 standard - why it pays off to invest in properly tested products

IEC 61111:2009 standard - why it pays off to invest in properly tested products