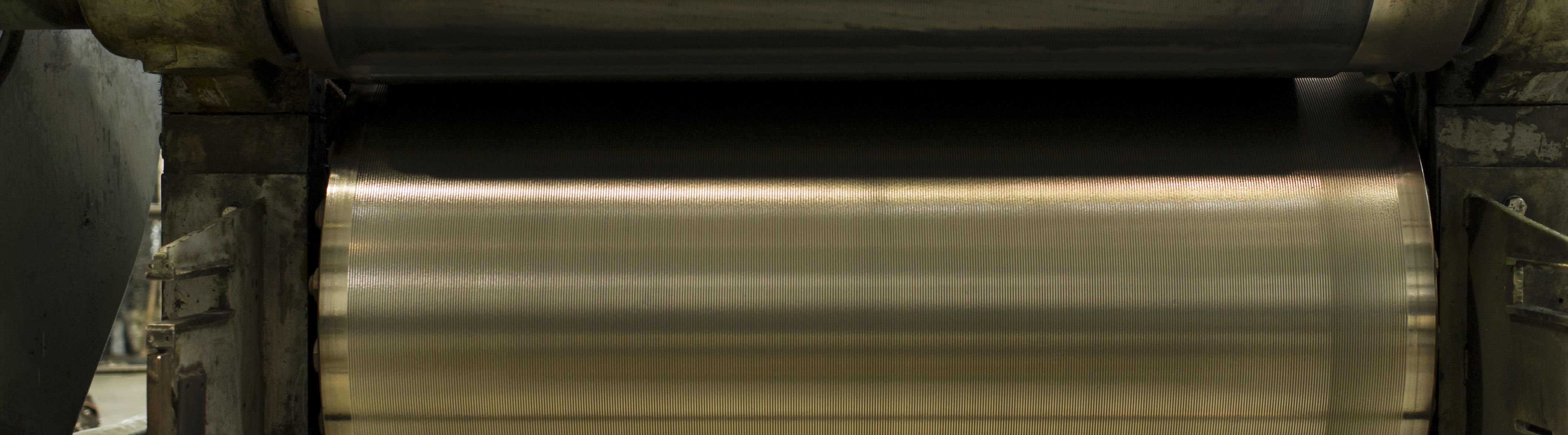

Since 2005, BOGUMA, LLC. is the Slovak manufacturer of rubber products. We supply to the whole world certified high quality rubber products, which do not have direct competition in the world, due to specific traditional production using rotocured technology.

We use rotocured vulcanisation technology, and our primary product comes in the form of a wound rolls. We focus on selecting superior rubber mixes from verified suppliers and react with great degree of flexibility to specific requirements of our customers.

We supply to a variety of markets: electro, energy, industry, sports. Can offer wide portfolio of products in four main categories: certified electrical insulating mattings and blankets, rubber flooring and rubber sheeting.

We are also able to create new products according to specific needs or requests of our customers. That is another reason why we are continuously widening the portfolio of our clients all over the world.

We transform first class quality rubber compounds using roto-cure technology into certified products. We respond flexibly to your requirements as a professional team of rubber specialists.

Mission

Your touch with us increases your safety.

We produce only high quality products that increase your protection in all environments used.

Vision

Values

We care, we notice and we act ethically.

Our values represent a complex of features embodied in our business and behavior. We put great emphasis on good relationships, both inside our company and among our business partners. We care about aspects of work and business environment, which exist in compatibility and propel our company forward. We care about self, about colleagues, and about the environment, in which we operate and do business. We keep our eyes and minds open to new opportunities and impulses, as well as to continuous improvement of our processes. We always behave ethically and respectably whether it is with our employees or within our supply-customer chain.

High quality production technology

High quality production technology

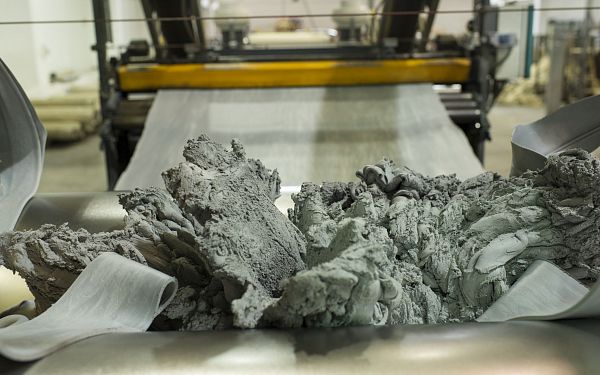

CALANDER LINE

We produce our rubber using rubber mixtures from suppliers that guarantee required quality and parameters, including certificates.

We first process the rubber mix on a line of two-cylinder machines that are unique and enable us to prepare rubber sheets, that make a basis for a quality product.

We leave these rubber sheets to mature for some time and they continue further into the vulcanisation process.

![]()

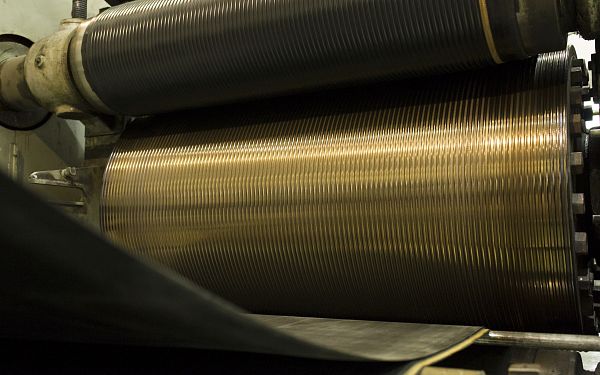

ROTOCURE PRESS

The vulcanisation process takes place in the rotocured presses. Those allow us to produce different thickness (up to 15 mm), width (up to 1400 mm) with variable design or top layer.

Our rotocured presses are managed by modern software, with which we have full control over the process including data backup.

![]()

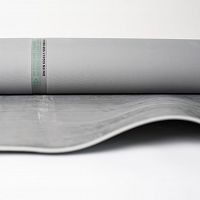

INSPECTION AND CUTTING TABLE

After the vulcanisation process, the rolls are placed on the control table, where edges are trimmed for required width and the roll is divided into individual lengths. During this process we check the correct thickness and make a visual assessment, so that final goods is guarynteed in the required quality.

We package the final product into a protective foil and move them onto paletts, or onto paletts with protective extension and attach them securely. At this stage the product is ready to be delivered to the customer.

Certified products

Certified products

Rubber Flooring

STN EN ISO 24341:2012

Our rubber flooring is in accordance with valid European standards specifying width, length, straigthness and flatness of sheets of rubber flooring.

STN EN ISO 24346:2012

We produce our rubber flooring in accordance with the European norm specifying the best overall thickness for different types of flexible rubber flooring.

STN EN 12199

In rubber flooring production we adhere to the specification valid for homogenous and heterogenous rubber flooring with design.

STN EN 13501-1

In producing flame retardant flooring we adhere to the classification of fire characteristics of construction products and construction elements, which in part one uses data from reaction to fire tests.

STN ISO 7619-1

We produce our rubber flooring in accordance with the ISO norm for rubber, vulcanised or thermoplastic elastomer, which specifies hardness (shore) by pressing in the tip of a hardness meter.

STN EN 14041

We produce our rubber flooring in accordance with the specification of essential characteristics for resilient, textile, laminate and modular multilayer floor coverings.

Rubber sheeting

STN EN ISO 24341:2012

Our rubber flooring is in accordance with valid European standards specifying width, length, straigthness and flatness of sheets of rubber flooring.

STN EN ISO 24346:2012

We produce our rubber flooring in accordance with the European norm specifying the best overall thickness for different types of flexible rubber flooring.

STN ISO 7619-1

In producing rubber sheeting we adhere to the ISO norm for rubber, vulcanised or thermoplastic elastomer, which specifies hardness (shore) by pressing the tip of the hardness meter.

STN 62 2000

In producing rubber sheeting we adhere to the norm, which specifies material sheets of rubber. We uphold the basic principles and values of parameters.

Electrical insulating matting

IEC 61111:2009

We produce our electrical insulating matting in accordance with the European norm for electrical strength. It is valid for rubber flooring made of elastomers and designed to protect workers at electrical installations.

STN EN ISO 24341:2012

Our electrical insulating matting adheres to valid European standards, which specify width, length, straigthness and flatness of sheets of rubber flooring.

STN EN ISO 24346:2012

We produce our electrical insulating matting in accordance with the European norm specifying the best overall thickness for different types of flexible rubber products.

STN ISO 7619-1

In producing the electrical insulating matting we adhere ti the ISO norm for rubber, sa riadime ISO normou pre gumu, vulcanised or thermoplastic elastomer, which specifies hardness (shore) by pressing in the tip of a hardness meter.

Electrical insulating blanket

IEC 61112:2009

We produce our electrical insulating blanket in accordance with the European norm for electrical strength. It is valid for rubber flooring made of elastomers and designed to protect workers at electrical installations.

STN EN ISO 24341:2012

Our electrical insulating blanket adheres to valid European standards, which specify width, length, straigthness and flatness of sheets of rubber flooring.

STN EN ISO 24346:2012

We produce our electrical insulating blanket in accordance with the European norm specifying overall thickness for different types of flexible rubber products.

STN ISO 7619-1

During producing the electrical insulating matting we adhere to the ISO norm for rubber, vulcanised or thermoplastic elastomer, which specifies hardness by pressing in the tip of a hardness meter.

MILESTONES

New rotocure steel belt

We have decided to significantly increase the production capacity of products with a smooth surface. By installing a new steel belt on one of our presses, we have increased the flexibility of supplying our products with a smooth surface.

ISO 9001

Because the quality of our products is very important to us and our customers, we have implemented a Quality Management System according to the ISO 9001:2015 standard and successfully passed the first certification by Bureau Veritas.

Yellow flooring S8

We have added a soft yellow to the color portfolio, which will subtly refresh every space. In addition to the portfolio where we already had classic black, gray and dark gray, we also have eye-pleasing colors - blue, green and red.

Celebration of 15 years

We celebrated 15 years since the start of the fully reconstructed rubber production in Bošany. The tradition of production by rotocuring goes back to 1958, when the first rotocure machine was manufactured in the Czechoslovakia.

Power plant in Mochovce

The nuclear power plant in Mochovce has chosen us as the supplier of Electrical Insulating Matting DEK4-H-1 and DEK3-S1-2 for the 3rd unit.

30 countries

Our client portfolio has reached thirty countries from all continents. In Asia and the Middle East, our electrical insulation blankets and sealing boards are most in demand.

Door to the market in South America

We enter the next continent as a supplier of quality rubber products and start trading with South America. Since then, the portfolio of our global business partners has been growing steadily.

Reconstruction of the first calander

We are reconstructing the first two-cylinder calender by replacing the engine, refurbishing the gearbox, replacing all bearings, gears and the cooling system.

Other certificates

We consistently monitor the quality of our products and obtain a certificate for the electrical insulation blanket EIP 0 according to the European standard IEC 61112:2009. We are starting to supply electrical insulating carpets to Stredoslovenská distribučná.

Entry into the asian market

During the years 2013 to 2015, we deliver the first large volumes of dielectric carpets dek4-s7-1 (14 containers) to asia and thus open a trade route to another continent.

Romanian hockey

We won the first large order abroad and successfully equipped it for a coin pattern flooring with type S8, for a new hockey stadium in Romania.

Plain investment

We enrich the production with an endless steel belt for a rotary press, which allows us to expand our product range, improve products with a smooth surface and gain more customers.

Zvolen stadium

We succesfully supply rubber flooring with coin surface S8, blue and grey in 6 mm thickness, for complete coverage of all floors on the sports stadium in Zvolen.

Continuous investment

We continue to invest in increasing production quality. We connect a machine to trim and control rubber product rolls for better preciseness and safety.

First quality certificate

From the beginning we put emphasis on superior product quality. As the first certificate we receive certificate for electrical insulating matting according to the IEC 61111:2002 norm. That opens the door for Slovak rubber to the world, where there is the greatest demand for elecrtical insulating matting.

The first product from the press

On the 2nd of November 2006, the production in the plant BOGUMA, Ltd. is ceremoniously launched. The first product to leave the rotocured press is rubber flooring type S2, a sample of which the boguma rubber lovers still keep.

Saving of rotocured production

Four rubber professionals aware of the value of rotocured production attain and reconstruct the unused machines of the Buzuluk company and rebuild the historical building (Koželužne Bošany) into a traditional rubber production plant. They establish a new company, BOGUMA, Ltd.

Post-revolution decay

After the velvet revolution, as an aftermath of privatisation, a prosperous rubber factory is divided into four independent companies with different portfolio. Rotocured press is on operation in Bratislava until 2004, when production is finally closed down.

Birth of rotocured technology

In 1958, the company Buzuluk in Komárov, Czech Republic, begins to manufacture the first high quality machines designed to manufacture rubber by rotocuring. The first produced machine is a rotocured press for matting. In times of greatest rubber boom in Czechoslovakia, 32 such machines are in operation.

Unbeatable rubber industry

Since its first establishment in 1905 in Bratislava, rubber production goes through all history crises (economic crises, plant fires, changes of owners, moving factories, second world wars). Rubber industry always survives and thrives. After ww2, it is rebuilt again, this time as one of the strategic socialist enterprises with own factory shops.

The birth of the first rubber

The first rubber plant was built by an Austrian company Gummi und Bellata Werke in Bratislava Petržalka. It is entered into the business registry as “Matador, production of rubber and caoutchouc products”, and becomes part of a cartel of rubber plants in the Austro-Hungarian Empire.